Advanced Cutting Tool Systems is a world leader in the special design and build of engineered cutting tool solutions. Advanced Cutting Tool Systems, established in 1970, provides the manufacturing industry with invaluable technical application expertise, service support, and demonstrated results.

The Advanced Cutting Tool Systems Sales Team and Application Experts collaborate and develop partnerships with customers; to provide the precise cutting tool solution for every challenge.

From point of inquiry through application performance, the Advanced Cutting Tool Systems design staff maintain a spirit of continuous improvement, innovation, and technical development; constantly seeking alternative, cost-effective cutting tool solutions to ensure customers remain competitive in a rapidly changing manufacturing environment.

Advanced Cutting Tool Systems offers a wide range of cutting tool products including:

40 Years of Innovative Cutting Tool Solutions

Advanced Cutting Tool Systems is a world leader in the special design and build of engineered cutting tool solutions. Established in 1970, Advanced Cutting Tool Systems provides the manufacturing industry with invaluable technical application expertise, service support and demonstrated results.

The Advanced Cutting Tool Systems Sales Team and Application Experts collaborate and develop partnerships with customers to provide the precise cutting tool solution forever challenge.

Experience • Innovation • Customer Satisfaction • Service

From point of inquiry through application performance, the Advanced Cutting Tool Systems design staff maintain a spirit of continuous improvement, innovation, and technical development constantly seeking alternative, cost-effective cutting tool solutions to ensure customers remain competitive in a rapidly changing manufacturing environment.

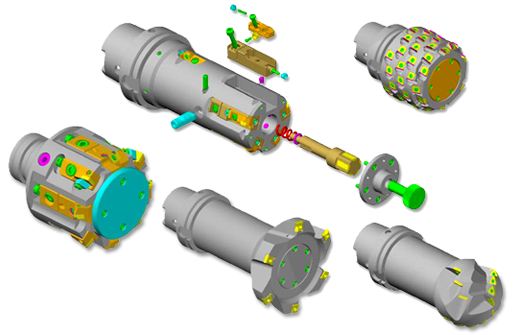

SPECIAL DESIGN & BUILD

One-Stop Supplier for Special Cutting Tool Solutions

Our ability to provide customer satisfaction through total service support drives all areas of Advanced Cutting Tool Systems. From the special design and engineering of precision cutting tools to total part processing and in-house inventory, Advanced Cutting Tool Systems functions as a one-stop supplier.

Advanced Cutting Tool Systems' services extend beyond production and product support to meet rapid delivery requests and reduce inventory through standard solutions.

More than 50 years of engineering experience

Utilize SolidWorks and AutoCAD CAD/CAM Software

Total Part Processing – From Spindle to Fixture

Tool Layout and Processing

ANTI-VIBRATION TOOLS IMPROVE STABILITY, INCREASE TOOL LIFE

2013-03-29 - Advanced Cutting Tool Systems

Are you experiencing vibration while milling or turning on your CNC or transfer line machines?

Advanced Cutting Tool Systems can help eliminate or reduce vibration due to unstable cutting tools, fixtures and spindles.

Please contact Advanced Cutting Tool Systems with your vibration problems and we will work with you to develop an engineered solution.

Our anti-vibration tools:

• Reduce or Eliminate Vibration

• Improve Part Finish

• Increase Tool Life

One-Stop Supplier for Special Cutting Tool Solutions

Our ability to provide customer satisfaction through total service support drives all areas of Advanced Cutting Tool Systems. From the special design and engineering of precision cutting tools to total part processing and in-house inventory, Advanced Cutting Tool Systems functions as a one-stop supplier.

Advanced Cutting Tool Systems' services extend beyond production and product support to meet rapid delivery requests and reduce inventory through standard solutions.

More than 50 years of engineering experience

Utilize SolidWorks and AutoCAD CAD/CAM Software

Total Part Processing – From Spindle to Fixture

Tool Layout and Processing