Campbell Spindle and Machine Repair

Many machine shops make Campbell spindles, machines and presses a prominent part of their day-to-day operations. Campbell equipment has a stellar, well-deserved reputation for delivering consistent results in even the most demanding work environments. They can make a valuable contribution to any organization’s efficiency and productivity.

If you’re looking for a trustworthy provider of Campbell equipment repair and refurbishment services, look no further than Colonial Tool Group. CTGI has been in business since 1929. We understand what it takes to keep machine tool equipment in peak operating condition. All repair and rebuild services are performed in-house by our team of expert technicians, engineers, assemblers and other well-trained, highly skilled professionals who have access to all the tools and resources they need to do the job right the first time.

Our Campbell Spindle Repair Services

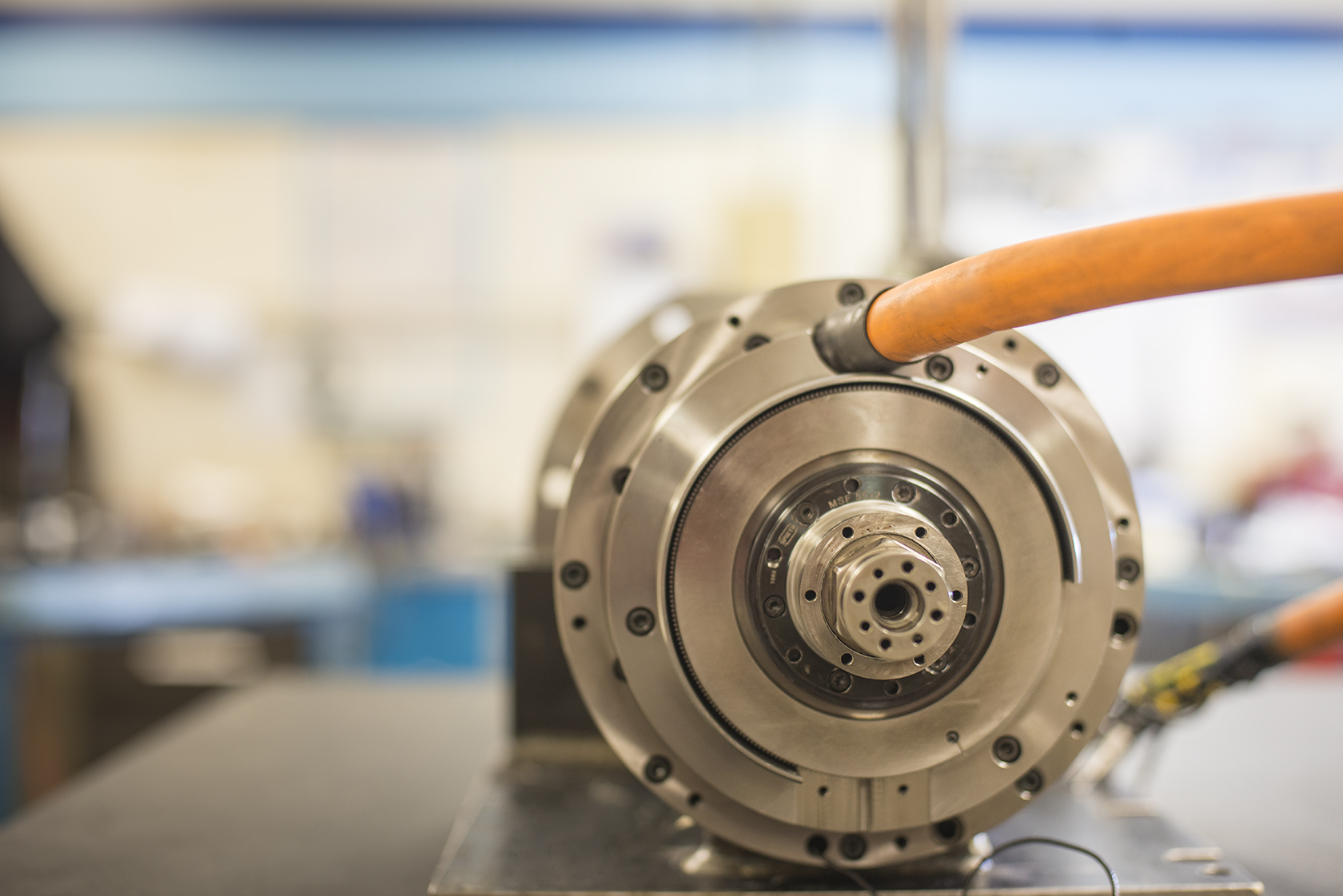

Our Campbell spindle repair services encompass all major models, such as the Campbell 2000, the ES-70, the 930H and the 930V. We’ll conduct a thorough internal and external assessment of the spindle, along with comprehensive testing to accurately diagnose the repair issue. We’ll rework any components that do not comply with original print tolerances and replace them if necessary. We’ll then perform final testing before packing the repaired unit and shipping it back to your facility.

Our Campbell Spindle Rebuild Processes

Are you looking for a cost-effective alternative to purchasing a new spindle? Our premium Campbell spindle rebuild services can give you a completely refurbished part that performs like new. Our assembler will pretest the unit to determine the current performance level of the spindle and its components, then disassemble it to get a firsthand look.

We’ll take pictures during each step of the process and send them to you along with a detailed inspection report. We’ll also include a “not to exceed” quote so you’ll know the maximum cost of your rebuilding project in advance. Once you give us the go-ahead, you can expect to receive your rebuilt spindle in three weeks or less.

Campbell Machine and Press Repair Service

Do you use Campbell 3-, 4- or 5-axis CNC machines in your shop? Do you use Campbell presses? Our premium Campbell machine and press repair services can troubleshoot and remedy common issues that prevent optimal performance. We can also offer a variety of machine refurbishment services, including rebuilding, retrofitting and remanufacturing. A refurbishment can provide an affordable solution for older machines where many of the components are still functioning properly.

We’re Committed to Maximizing Equipment Uptime

At Colonial Tool Group, we understand a malfunctioning press or spindle can bring your entire operation to a standstill. Every member of our team is committed to completing your repair or rebuild project as quickly as possible so you can maintain your tight production schedules and minimize equipment downtime. We can also increase the lifespan of your equipment, which will lengthen the time between replacements.

Contact Colonial Tool Group today to learn more about our vast array of Campbell repair and rebuild services — and how they can contribute to the profitability of your machine shop.